However, it’s especially prominent in the medical device industry. CNC machining offers manufacturers a wide variety of benefits that are crucial to their success.

What Is Medical Device Manufacturing?

Medical device manufacturing is the process of designing, producing, and distributing these products. It involves many different stages – from design to creating prototypes with assistance from additive printing machines, preparing for production, building the product itself, and distribution.

The materials used in this process should be sterile, meaning they can’t contain any microorganisms or bacteria. That’s why machines that produce medical devices have special safety features like laminar flow hoods and other ventilation measures to create a safe environment.

The medical industry has undergone some massive changes in the past decade.

Medical device manufacturing companies have started using CNC machining more often due to their precision capabilities, increased speed of production, and lower prices compared with other methods of medical device assembly. This means that almost every major company now owns one or more CNC machines which makes them capable of creating highly accurate and detailed parts on a large scale without compromising quality.

Importance for the Medical Industry

CNC machining for the medical industry plays an integral role, adding to the overall quality of medical devices. The fact that there are millions of products manufactured using CNC machining is a testament to its importance in the medical device manufacturing industry.

It’s an efficient, reliable method that allows manufacturers to create high-precision parts. When you consider that countless lives are saved by medical devices each year, it quickly becomes clear why this technology is so popular amongst medical manufactures; lives depend on their products. If we take India as an example where lots of medical devices are being imported, there are many regulations where importers should have device approval in India, also the medical device product registration there is overseen by the Central Drugs Standard Control Organization (CDSCO).

Increased Precision and Accuracy in Production

When it comes to medical devices, a few thousandths of an inch can make all the difference.

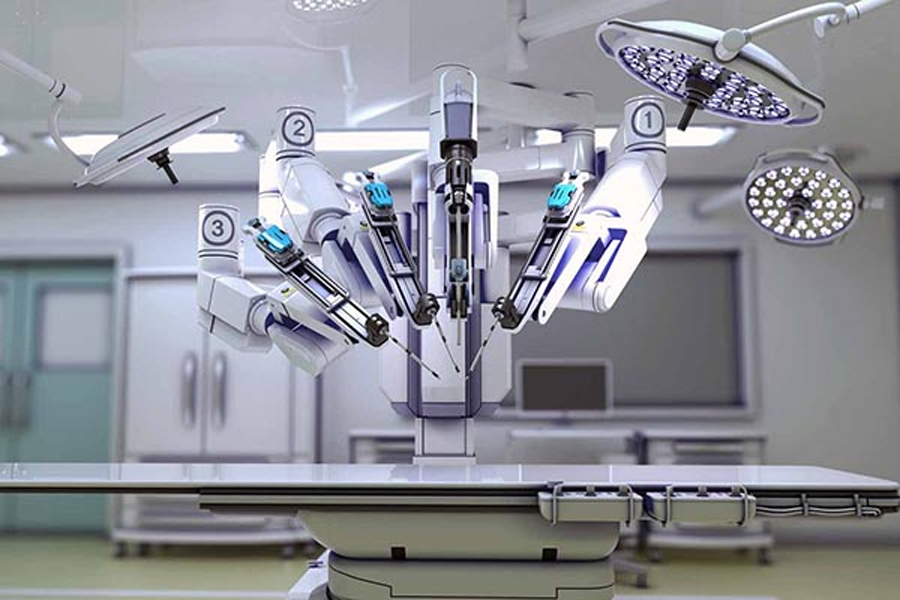

If a surgeon is using a surgical instrument to make delicate incisions in a patient’s body, for example, they will want to be absolutely sure that there are no imperfections in the device that could affect its function. CNC technology allows manufacturers to create products with increased precision and accuracy, which is vital for high-quality medical devices.

Increased Flexibility for Manufacturers in the Product Process

Not only does CNC machining allow companies to produce parts with increased precision and accuracy, but it also gives them far more flexibility when it comes to production.

For example, instead of having to set up the machine tools for a complicated, specific task, it can instead be programmed to take on a variety of tasks. Manufacturers will have the ability to quickly change from one process to another, allowing them to efficiently respond to changes in demand and ultimately increase their profit margins.

Safety and Durability

Many medical devices are made with metal parts that are created through CNC machining to ensure safety and durability.

These devices can range from medical needles and syringes to more complicated devices such as surgical equipment. Since the medical device manufacturing industry is a billion-dollar business, it’s no wonder that companies are using CNC machining for their parts.

Reduces Waste While Increasing Quality

The CNC machining process has been used for decades and has allowed companies to do other types of secondary operations, such as heat treating and coating, helping them meet the strict guidelines set by the FDA.

More Cost-Effective Than Conventional Manufacturing Methods

Because CNC Machining reduces waste, it’s more cost-effective than conventional manufacturing methods.

The typical machining process involves removing excess stock from a raw material, which produces scrap. CNC machining leaves less material behind, so there is less waste to dispose of.

And because there are fewer raw materials, companies can reduce the amount of material purchased and purchased in bulk for more savings

Although some companies may want to purchase their own equipment for CNC machining, many choose to outsource this job to a shop that specializes in it. The benefit of doing so is that they can save money on equipment and purchasing costs.

Future of Medicine

Smart technology has been the focus of medical innovation and research in recent years, becoming an essential part of modern healthcare by allowing doctors to identify illnesses, health patterns, and, most significantly, life-saving therapies. Artificial intelligence-driven gadgets such as wearables that can monitor a person’s condition, predict and detect abnormalities and infections quickly, as well as voice and large-scale data communication are examples of this technology.

Medical device manufacturing is set to benefit greatly from engineering advances. New technologies in the manufacturing sector such as CNC machining, with a big boost from the needs of COVID-19 and investments in the health sector, will affect the medical industry as well.

CNC machining for the medical device industry is improving and innovating constantly. New products and improvements are developed every day. People live longer because of technical improvements in the health sector and new medical devices will always be important.

In Conclusion

If you’re ready to invest in new equipment for your machine shop, here are some reasons why CNC machining is the best choice.

The medical device manufacturing industry accounts for a large portion of global economic output. In fact, it is often said that one out of every six people in the United States works either directly or indirectly in the field of medical devices. As industries continue to move more toward automation, the demand for CNC machining services will increase exponentially.

CNC machining is one of several key technologies that have revolutionized the medical device manufacturing industry. With these cutting-edge new advancements, medical device manufacturers are able to create highly accurate parts for everything from surgical equipment to replacement joints and pacemakers. Hopefully, this article has given you a better understanding of the role that CNC machining services play in producing these complex parts.

Comments

comments