According to a study published in the International Journal of Pharmaceutics, conventional drug dosage forms, such as capsules and tablets, are usually associated with low bioavailability, side effects, and frequent application, resulting in patient non-adherence to medication.

According to a study published in the International Journal of Pharmaceutics, conventional drug dosage forms, such as capsules and tablets, are usually associated with low bioavailability, side effects, and frequent application, resulting in patient non-adherence to medication.

On the other hand, advanced drug delivery systems can administer specific and consistent amounts of medications, improving patient compliance with prescribed medication. Liquid dosing systems promise to improve drug delivery. This article will discuss how liquid dosing systems can attain this goal.

What Is Liquid Dosing?

Liquid dosing is a high-tech solution that utilizes liquid pumps and other flow instruments for greater precision. It’s used in different applications, such as in the food industry to add flavorings, the petrochemical industry for dosing additives, and the healthcare industry for drug delivery.

What Are Liquid Dosing Systems?

Liquid dosing systems come in various forms. The most common ones are medical infusion pumps and liquid diaphragm pumps. Medical infusion pumps draw fluid from a standard intravenous fluid (IVF) bag and control the flow rate for continuous therapy. An infusion pump can use any size of IVF bag to deliver fluids at a very fast or very slow infusion rate.

On the other hand, liquid diaphragm pumps provide precise quantities of liquid media for proper dosing. They allow safe, clean, and accurate handling of corrosive and neutral liquids. These pumps are easily calibrated with programmable timers, cycle settings, and control options to generate highly reproducible results.

Furthermore, pharmacologists use them to produce liquid drugs tailored to patients’ treatment needs.

Ways Liquid Dosing Systems Improve Drug Delivery

Liquid dosing systems play an essential role in prompt and precise drug delivery. Patients obtain the highest level of therapeutic care by preventing over- and under-drug dosing. Below are the various ways liquid dosing systems can help improve drug delivery.

1. Accurate Drug Delivery Through Liquid Pumps

Medical liquid pumps provide precise dosing with low flow rates or micro-dosing intravenous fluids. They allow dispensing of liquid drugs via narrow cannula needles and highly viscous fluids. Furthermore, many healthcare facilities utilize single-use pumps with seamless integration into the delivery line. Because of the consistent pump performance of single-use liquid pumps, they’re a popular form of liquid drug delivery. With single-use liquid pumps, rapid fluid changes won’t cause cross-contamination. Once the fluid pack is empty, healthcare workers can dispose of the pump, line, and container.

2. Increased Patient Medication Compliance

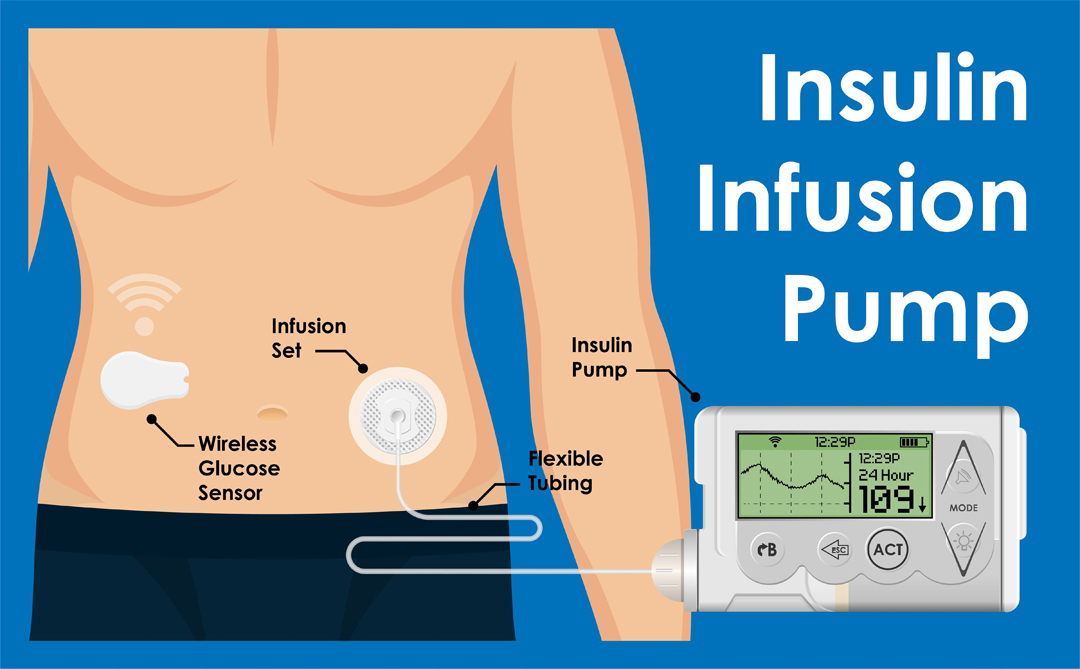

Liquid drug dosing is vital in medical treatment. Automated liquid dosing systems greatly benefit patients needing slow, regular liquid medication administration.For instance, diabetic patients who need insulin therapy can use liquid drug dosing for continuous subcutaneous insulin injection using liquid pump systems. Liquid drug dosing eliminates the need for multiple daily insulin pen injections in various body parts.

Patch pumps increase compliance among patients with diabetes. Because patch pumps aren’t disconnected, they promote a steady insulin supply to boost therapeutic success. A patch pump reduces fluctuations associated with vertical infusion sets by reducing hydrostatic pressure.

Cancer patients also benefit from medical research involving continuous drug delivery using liquid dosing systems in chemotherapy. Liquid dosing systems improve targeted drug delivery to specific tissues to attain therapeutic benefits. Furthermore, they reduce side effects associated with toxic drug levels. With automated, precise, and reliable liquid drug dosing, cancer patients receive excellent care, boosting compliance and the patient’s quality of life.

3. Adjustable Flow Rates For Flexible Liquid Drug Delivery

Many models of liquid dosing systems have adjustable rates, promoting flexible liquid drug delivery. The best ones have bi-directional and continuous flow with high pressure and vacuum capability. Healthcare and pharmaceutical researchers can depend on adjustable flow rates and other robust dosing system features in designing new devices for liquid drug delivery. For instance, low-torque liquid dosing systems with rotary action can help them distinguish the accurate flow rate, dose volume, or the number of boluses for liquid drugs.

Medical infusion pumps are designed to infuse small or large volumes of drugs, such as antibiotics, chemotherapy drugs, pain relievers, and hormones. They’re also used to infuse nutrients for patients with special nutritional needs. These patients need enteral infusion pumps for liquid nutrients or drug delivery through the digestive system. Such capabilities of liquid dosing systems make drug delivery flexible for varying patients’ needs.

4. Safe Drug Delivery

Liquid dosing systems have a lock-out system and other safety features. The lock-out feature ensures the liquid container can’t be used for another dispenser or inappropriate dispense route. Single-use pumps have consistent performance with a significant safety margin to avoid drug delivery errors. The dosing systems for liquid oral medications provide precise dosages for safety. The primary components include the riser tube, dosing head, closure, and container. Once the precisely measured liquid has reached the dosing head, the opening point closes for effective, safe dosing.

Many infusion pumps have operator alerts, like an alarm system and air-in-line detector, activated in case of a drug delivery problem. For instance, some infusion pumps alert people when the tubing has air, blood, or blockage during fluid delivery. On the other hand, liquid diaphragm pumps can safely handle dangerous chemicals, such as high-temperature liquids. Their design features prevent leaks, and the absence of rotating components like mechanical seals and gaskets makes them less prone to wear and tear or sudden failure.

5. High-Quality Drug Delivery With Certifications

Aside from safety standards, liquid dosing systems can help improve drug delivery in compliance with industry requirements. A high-quality liquid diaphragm pump has certification profiles from regulatory agencies, such as the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO).

6. Ease Of Use and Portability

Portability and ease of use promote convenience for healthcare professionals and patients. Many models and brands of liquid dosing systems are designed to be installed and transported quickly and safely. For instance, portable medical infusion pumps can be mounted on a trolley for safe and easy transportation.

Conclusion

Liquid dosing systems improve drug delivery because of their robust features, promoting drug dosing accuracy and precision. Healthcare facilities, pharmacies, and laboratories use them for a broad range of applications, improving the overall quality of patient care. Choosing the right liquid dosing system entails extensive research to ensure the highest quality, great features, and safety.