Iron is a critical element that plays a vital role in various biological and environmental processes. It is the most abundant element by mass in the Earth’s core and the fourth most abundant in the Earth’s crust, making it a key component in many geological and biological systems. In living organisms, iron is essential for numerous metabolic processes, including DNA synthesis, respiration, and photosynthesis in plants. It is a crucial part of hemoglobin in erythrocytes, facilitating oxygen transport in the blood, and is recycled by macrophages in the spleen, liver, and bone marrow. Iron’s ability to undergo oxidation-reduction reactions makes it indispensable in cellular energy generation and as a cofactor in various enzymes. However, iron must be carefully regulated within the body to prevent toxicity, as excess iron can catalyze the formation of harmful free radicals. The regulation of iron metabolism involves complex mechanisms, including the action of the peptide hormone hepcidin, which controls iron absorption and release. Iron also plays a significant role in ocean biogeochemistry, influencing primary productivity and the cycling of carbon and nitrogen. Thus, iron’s ubiquity and versatility underscore its fundamental importance across different domains of life and the environment.

Physical and Chemical Properties of Iron

It is a fundamental element widely used in various industries due to its unique physical and chemical properties. Understanding these properties is essential for its effective application in construction, manufacturing, and technology. Below is a detailed overview of iron’s physical and chemical properties:

1. Physical Properties

It is a lustrous, ductile, and malleable metal with a high melting point of 1538°C and a boiling point of 2862°C, making it suitable for high-temperature applications. The density of iron is approximately 7.87 g/cm³, which contributes to its strength and durability. Iron can exist in different crystalline forms, primarily body-centered cubic (BCC) at room temperature and face-centered cubic (FCC) at higher temperatures, which influence its mechanical properties. Additionally, iron’s physical properties can be significantly altered through alloying and thermal treatments, enhancing its utility in various industrial applications.

2. Chemical Properties

Iron is chemically versatile, existing in multiple oxidation states, primarily Fe(0), Fe(II), and Fe(III), which contribute to its rich chemical behavior. It readily forms complexes with ligands containing oxygen, nitrogen, and sulfur, which is essential for its role in biological systems such as hemoglobin and cytochromes. Iron’s propensity to undergo redox reactions makes it a key player in processes like respiration and photosynthesis. However, iron’s reactivity also poses challenges, such as its tendency to corrode, forming iron oxides like rust. This reactivity is harnessed in various electrochemical applications, including batteries and fuel cells, where iron’s redox properties are exploited for energy storage and conversion.

Occurrence and Sources

Natural Occurrence in the Earth’s Crust

It is primarily found in the form of various combined ores, including oxides and sulfides. The most significant iron-containing minerals are hematite (Fe2O3), magnetite (Fe3O4), and goethite (FeO2H), which belong to the oxide group, while pyrite (FeS2) and marcasite (FeS2) are part of the sulfide group. Iron is also present in meteorites, other planets, and the sun, indicating its widespread occurrence in the universe. Additionally, iron can be found in both sea and fresh water, with certain springs containing high concentrations of iron being classified as medicinal iron springs.

Common Ores (Hematite, Magnetite)

Hematite and magnetite are the most common and economically significant iron ores. Hematite, or red iron ore (Fe2O3), is known for its high iron content and is often used in the production of iron and steel. Magnetite (Fe3O4), also known as loadstone, is another major iron ore with strong magnetic properties, making it valuable for various industrial applications. These ores are often found in banded iron formations (BIFs), which are layered sedimentary rocks composed of alternating layers of iron-rich minerals and silica. The formation of these ores can involve complex geological processes, including hydrothermal activity and the oxidation of iron-bearing minerals.

Methods of Extraction

The extraction of iron from its ores involves several methods, depending on the type and composition of the ore. For high-grade ores, direct metallurgical processing is common, while low-grade ores require beneficiation processes such as gravitational, magnetic, and flotation separation to increase the iron content and reduce impurities. One innovative method involves microwave fluidization roasting, which enhances the formation of microcracks in the ore, facilitating the conversion of weakly magnetic hematite into strongly magnetic magnetite. This process is followed by magnetic separation to obtain high-quality iron concentrates. Additionally, chemical reduction methods, such as using carbon monoxide to reduce hematite to magnetite, are also employed to beneficiate iron ores.

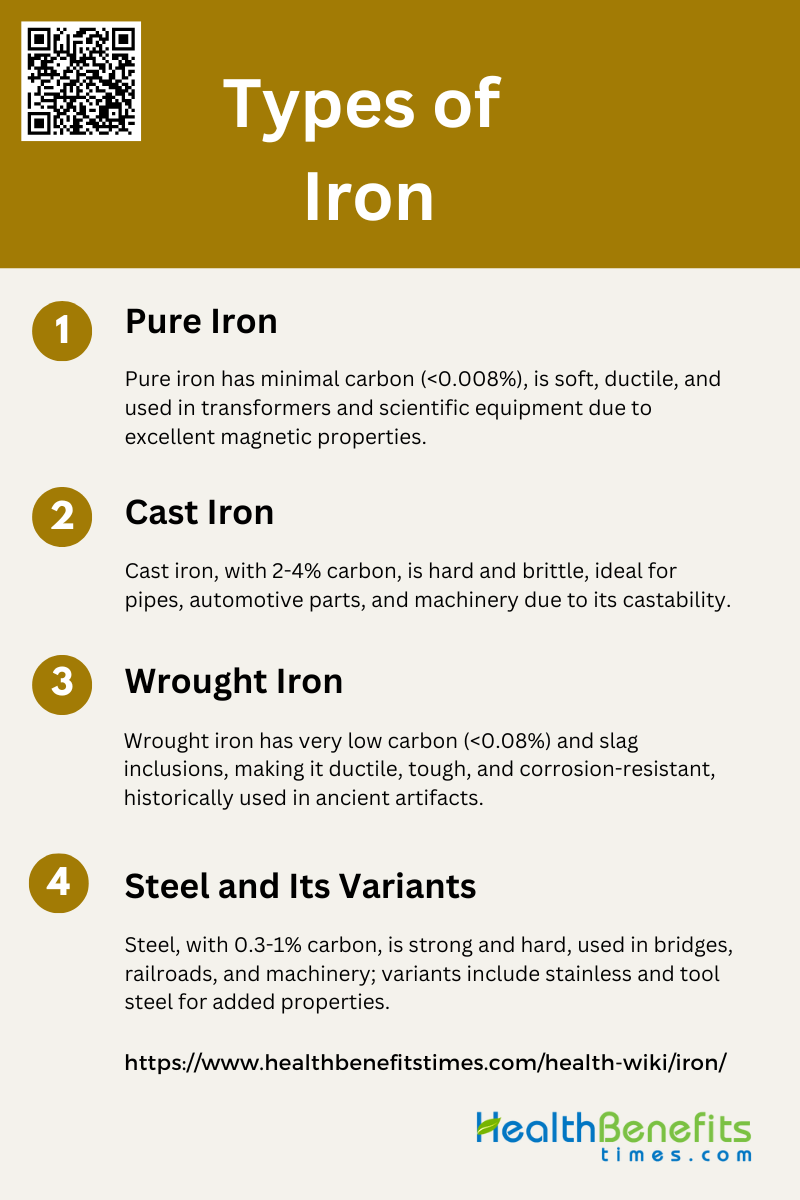

Types of Iron

Understanding the different types of iron is crucial for selecting the right material for specific industrial, construction, or manufacturing needs. Below is a list of the primary types of iron and their characteristics:

1. Pure Iron

Pure iron, also known as commercially pure iron, is characterized by its minimal carbon content, typically less than 0.008%. This low carbon content results in a soft, ductile metal with excellent magnetic properties and high electrical conductivity. Pure iron is primarily used in applications where these properties are essential, such as in electrical transformers and certain types of scientific equipment. Historically, the concept of pure iron was linked to the idea of purification by fire, a notion that persisted until the 19th century when the chemical characterization of iron by its carbon content was established.

2. Cast Iron

Cast iron is an iron-carbon alloy with a carbon content typically between 2% and 4%. This high carbon content gives cast iron its characteristic hardness and brittleness. Cast iron is known for its excellent castability, making it ideal for complex shapes and large structures. It is widely used in the manufacturing of pipes, automotive components, and machinery. The comprehensive guide on the properties and selection of cast irons highlights their diverse applications and mechanical properties, which are extensively documented in technical literature. Cast iron’s historical significance is also notable, as it was one of the primary materials used during the early stages of industrialization.

3. Wrought Iron

Wrought iron is a form of iron with very low carbon content, typically less than 0.08%, and includes fibrous inclusions known as slag. This composition gives wrought iron its unique properties, such as high ductility, toughness, and resistance to corrosion. The production of wrought iron involves heating iron ore with charcoal, resulting in a material that is almost pure iron with a slag matrix. Wrought iron was extensively used in ancient artifacts and had a significant impact on the progress of civilization due to its mechanical properties and ease of fabrication. Its use declined with the advent of more advanced steelmaking techniques in the mid-19th century.

4. Steel and Its Variants

Steel is an iron-carbon alloy with a carbon content typically between 0.3% and 1%. The addition of carbon significantly enhances the strength and hardness of the metal, making steel a versatile material for a wide range of applications. The development of steelmaking processes, such as the Bessemer process and the open-hearth process in the mid-19th century, revolutionized the production of steel, making it more affordable and available in large quantities. This led to an explosion in industrialization, including the construction of bridges, railroads, and machinery. Steel variants, such as stainless steel and tool steel, further expand its applications by offering additional properties like corrosion resistance and enhanced durability.

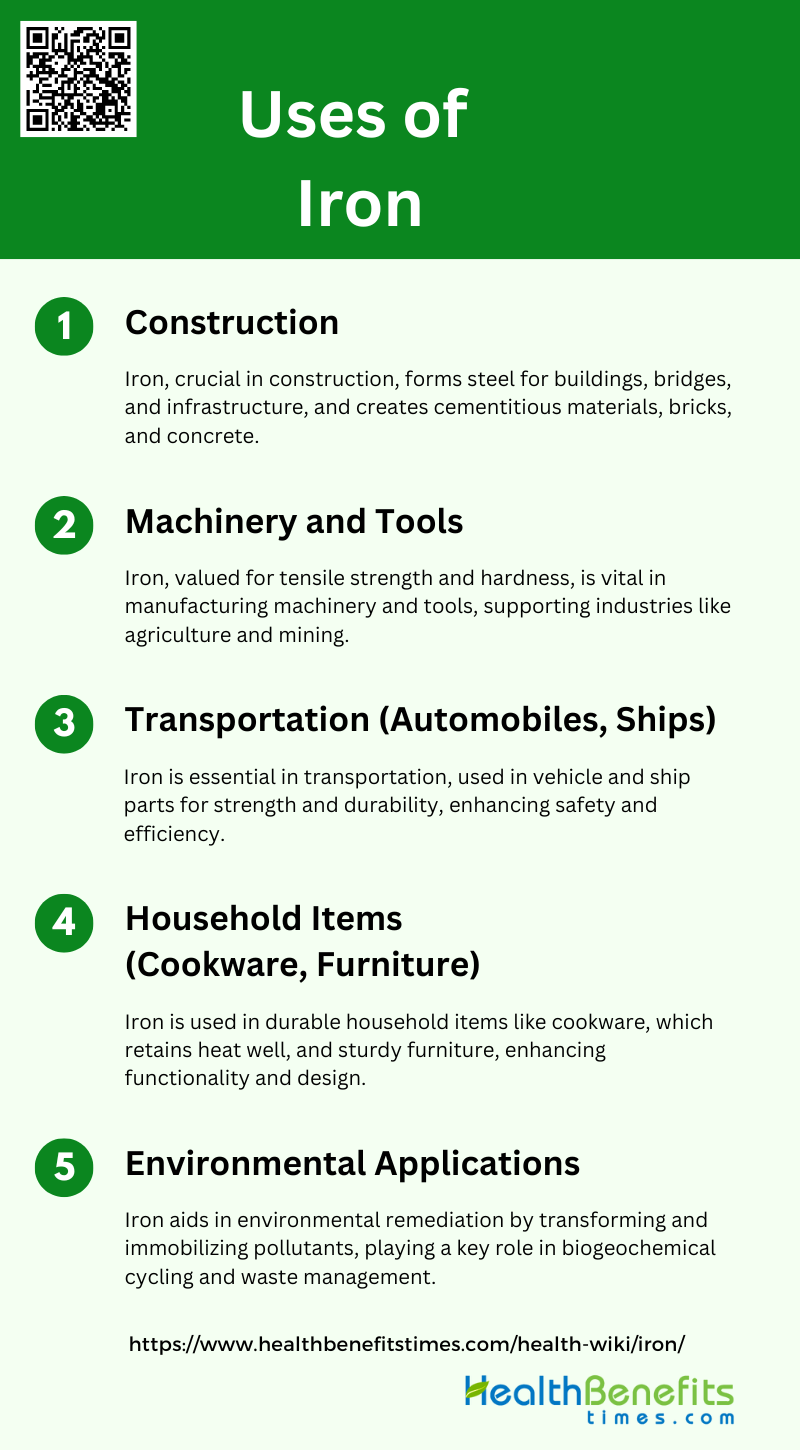

Uses of Iron

From construction to manufacturing, iron plays a crucial role in numerous applications. Below is a list of the primary uses of iron:

1. Construction

Iron plays a crucial role in the construction industry, primarily due to its strength, durability, and versatility. It is extensively used in the production of steel, which is a fundamental material for constructing buildings, bridges, and other infrastructure. Iron-based materials, such as iron ore tailings, are also utilized in the production of cementitious materials, bricks, and concrete, providing economic and environmental benefits by reducing waste and saving natural resources. Additionally, innovative materials like iron-based shape memory alloys (Fe-SMA) are being explored for their potential in prestressing and strengthening techniques, offering enhanced corrosion resistance and fatigue resistance. Overall, iron’s contribution to construction is indispensable, supporting both traditional and advanced building practices.

2. Machinery and Tools

Approximately 20% of global iron entering use is devoted to industrial machinery, highlighting its importance in this sector. The versatility of iron allows it to be used in various forms, including cast iron and steel, to produce a wide range of tools and machinery parts. These iron-based components are essential for the functioning of industries such as manufacturing, agriculture, and mining, where durability and reliability are paramount. The continuous development of iron-based materials ensures that machinery and tools remain efficient and effective in their applications.

3. Transportation (Automobiles, Ships)

Around 24% of global iron entering use is dedicated to transport equipment, underscoring its significance in this field. Iron and steel are used to manufacture various parts of vehicles, including the chassis, engine components, and body panels, due to their strength and ability to withstand high stress. In shipbuilding, iron-based materials provide the necessary durability and resistance to harsh marine environments. The use of iron in transportation not only enhances the safety and performance of vehicles and vessels but also contributes to the overall efficiency and sustainability of the industry.

4. Household Items (Cookware, Furniture)

Cast iron cookware, for example, is renowned for its ability to retain and evenly distribute heat, making it a popular choice for cooking. Iron is also used in the manufacturing of furniture, providing sturdy and long-lasting frames for items like beds, tables, and chairs. The versatility of iron allows it to be molded into various shapes and designs, catering to both functional and aesthetic needs in household items. This widespread use of iron in everyday products highlights its importance in enhancing the quality and longevity of household goods.

5. Environmental Applications

Mixed-valent iron minerals, such as magnetite and green rust, are used in environmental sciences for their ability to transform and immobilize pollutants. These minerals are essential in biogeochemical cycling and are actively researched for their potential in environmental remediation strategies. Additionally, iron compounds are utilized in the development of materials for adsorption, catalysis, and emulsions, contributing to environmental protection efforts. The use of iron in these applications demonstrates its versatility and importance in addressing environmental challenges and promoting sustainability.

Dietary sources of iron

It is important to include adequate iron in your diet to prevent deficiencies and maintain overall health. Below is a list of dietary sources of iron, categorized into animal and plant sources:

1. Animal Sources (Heme Iron)

Heme iron, primarily found in animal products, is a crucial dietary component due to its high bioavailability. Red meat, particularly beef and pork liver, is an excellent source of heme iron, with pork liver containing approximately 2.3 mg/100 g of heme iron. Additionally, cooked blood curds from pork and chicken are among the richest sources, providing 9.2 and 15.4 mg/100 g, respectively. Heme iron is absorbed more efficiently than non-heme iron, facilitated by the presence of heme carrier protein 1 (HCP 1) in the duodenum. This efficient absorption is vital for maintaining adequate iron levels, especially in populations with high meat consumption. However, excessive intake of heme iron has been linked to an increased risk of cardiovascular diseases.

2. Plant Sources (Non-heme Iron)

Non-heme iron, predominantly found in plant-based foods, is a significant dietary iron source, especially in regions where meat consumption is limited due to economic or cultural reasons. Legumes, such as soybeans, contain ferritin, a form of non-heme iron that can be an effective iron supplement. However, the bioavailability of non-heme iron is generally lower than that of heme iron and can be further reduced by the presence of phytates and tannins in plant foods. Strategies to enhance the iron nutritional value of plants include plant breeding, genetic modification, and improving iron bioavailability. Despite these challenges, non-heme iron remains a crucial component of the diet, particularly for vegetarians and those in developing countries.

Role of iron in the Human Body

It is essential for the production of hemoglobin, which transports oxygen in the blood, and myoglobin, which supplies oxygen to muscles. Below is a list of the key roles iron plays in maintaining health:

1. Oxygen Transport and Storage

Approximately 70% of the body’s iron is bound to hemoglobin in red blood cells, which is essential for transporting oxygen from the lungs to tissues and organs. Hemoglobin binds to oxygen in the lungs and releases it in tissues where it is needed, facilitating cellular respiration. Additionally, iron is a component of myoglobin, a protein that stores oxygen in muscles, ensuring an adequate supply during physical activity. The efficient transport and storage of oxygen are vital for maintaining cellular functions and overall metabolic processes.

2. Energy Production

It is a component of cytochromes and iron-sulfur clusters, which are essential for oxidative phosphorylation and ATP production. This process is crucial for converting nutrients into usable energy, particularly during physical exertion. Iron deficiency can impair energy metabolism, leading to fatigue and decreased physical performance. Therefore, maintaining adequate iron levels is essential for optimal energy production and overall metabolic health.

3. Enzyme Function

Iron is a critical cofactor for numerous enzymes involved in various biochemical processes, including DNA synthesis, neurotransmitter production, and cellular respiration. Enzymes such as ribonucleotide reductase, which is essential for DNA synthesis, and cytochrome P450, involved in drug metabolism, require iron for their activity. Iron-dependent enzymes also play a role in the synthesis of hormones and amino acids, highlighting the importance of iron in maintaining cellular and systemic functions. The proper functioning of these enzymes is vital for growth, development, and recovery from illnesses.

4. Immune System Support

It supports the proliferation and maturation of immune cells, particularly lymphocytes, which are crucial for adaptive immunity. Iron also plays a role in the production of reactive oxygen species (ROS) by neutrophils, which are used to kill pathogens. However, iron levels must be tightly regulated, as both iron deficiency and overload can impair immune function and increase susceptibility to infections. Thus, maintaining balanced iron levels is critical for effective immune responses and overall health.

5. Cognitive Function

It is involved in the synthesis of neurotransmitters such as dopamine, norepinephrine, and serotonin, which are essential for mood regulation, attention, and cognitive processes. Iron deficiency, particularly during critical periods of brain development, can lead to cognitive impairments and developmental delays. Adequate iron levels are necessary for maintaining optimal brain function, supporting learning, memory, and overall mental health.

6. Growth and Development

It supports the production of hemoglobin and myoglobin, which are essential for oxygen delivery to growing tissues. Iron also plays a role in cellular proliferation and differentiation, processes that are vital for tissue growth and repair. Iron deficiency during critical growth periods can lead to anemia, impaired growth, and developmental delays, underscoring the importance of adequate iron intake for healthy development.

Recycling and Sustainability

Iron recycling processes

One innovative method involves compressing dispersed iron scraps into iron scrap cakes, which are then melted and cast into sound castings, resulting in higher material yield rates and reduced environmental pollution. Another approach recycles iron from pickling waste acid through extraction and spray pyrolysis, producing high-purity Fe2O3 and recovering hydrochloric acid, thus achieving zero emissions of water and solid waste. Additionally, the recycling of iron-bearing waste materials in the iron ore sintering process has been optimized to reduce hazardous element emissions and improve material utilization. Fluidized roasting coupled with magnetic separation has also been effective in recovering high-quality iron from hazardous tailings, transforming waste into valuable resources. These methods collectively highlight the progress in iron recycling technologies, emphasizing cleaner production and resource efficiency.

Benefits of recycling iron

Recycling iron offers numerous environmental, economic, and social benefits. By converting iron scraps into reusable forms, such as iron scrap cakes, the process significantly reduces material costs, energy consumption, and environmental pollution compared to using dispersed iron scraps. Additionally, recycling iron helps in achieving a circular economy by reducing the need for primary iron production, which in turn lowers CO2 emissions, energy usage, and iron ore extraction. Advanced technologies like suspension roasting-magnetic separation (SRMS) further enhance the efficiency of iron recovery from iron tailings, contributing to resource conservation and environmental protection. Moreover, the recycling of iron plays a crucial role in various biological and ecological processes, such as the recycling of iron by marine animals in the Southern Ocean, which supports primary productivity in iron-limited regions. Overall, the recycling of iron not only conserves natural resources but also promotes sustainable industrial practices and environmental stewardship.

Sustainable practices in iron mining and production

The development of the Energy Impact Index (EII) provides a comprehensive tool to assess the sustainability of iron mining projects by considering factors such as energy consumption and CO2 emissions. Additionally, innovative approaches like using ammonia for iron oxide reduction offer promising pathways to green steel production, significantly reducing CO2 emissions. The integration of sustainable water management practices, as seen in South African mining companies, further highlights the importance of resource efficiency and environmental stewardship. Moreover, the adoption of hydrogen as a reductant in iron production, particularly in regions with abundant renewable energy, can enhance global decarbonization efforts and create new economic opportunities. These practices, along with the implementation of sustainability indicators and improved environmental management tools, are crucial for advancing the sustainability of the iron and steel industry.