Ammonia (NH₃) is a colorless, pungent gas composed of nitrogen and hydrogen. It is the simplest stable compound of these elements and plays a crucial role in various biological and industrial processes. Ammonia is a common nitrogenous waste in nature and is essential for the synthesis of amino acids and nucleotides, which are fundamental to life. Industrially, it is primarily produced through the Haber-Bosch process and is extensively used in agriculture as a fertilizer, with about 70% of the global production dedicated to this purpose. Additionally, ammonia is utilized in the manufacture of explosives, textiles, and cleaning agents. Despite its widespread use, ammonia is highly toxic and can cause severe health issues upon exposure, including respiratory distress and skin burns.

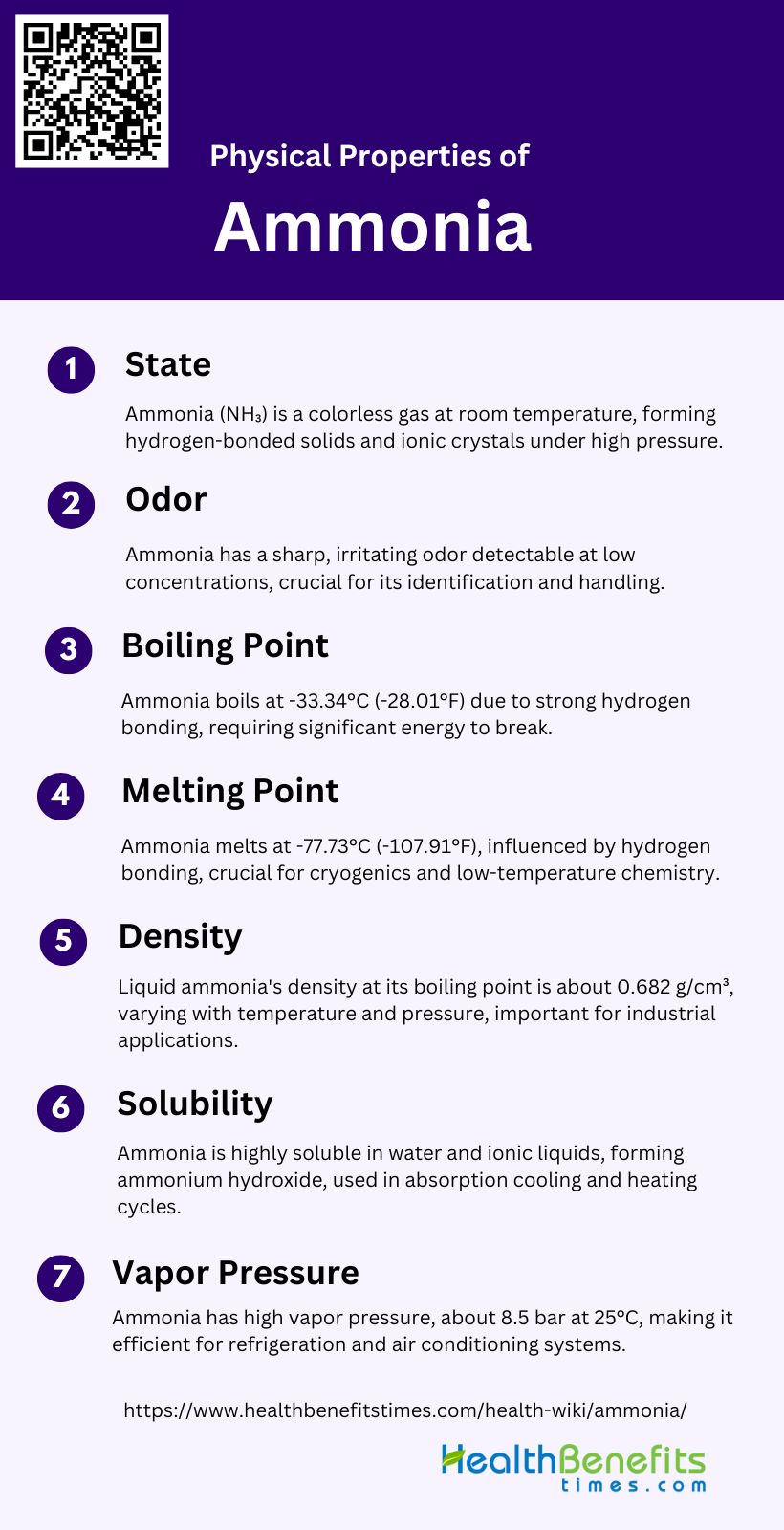

Physical properties of Ammonia

Ammonia is a colorless gas with a distinct, pungent odor. It is highly soluble in water and forms a basic solution known as ammonium hydroxide. Below are some key physical properties of ammonia:

1. State

Ammonia (NH₃) is a colorless gas at room temperature and atmospheric pressure. It is highly associated due to strong intermolecular hydrogen bonding, which significantly influences its thermophysical properties. Under high pressure, ammonia can form hydrogen-bonded solids and even ionic crystals, consisting of alternate layers of NH₄⁺ and NH₂⁻ ions. These ionic phases are stable over a wide range of pressures, making ammonia an interesting subject for studies in planetary physics and high-pressure chemistry.

2. Odor

This characteristic smell is due to the presence of free ammonia molecules in the air, which can be quite sharp and unpleasant. The odor is a significant factor in its identification and handling in various industrial and laboratory settings.

3. Boiling Point

The boiling point of ammonia is -33.34°C (-28.01°F) at standard atmospheric pressure. This relatively low boiling point is due to the strong hydrogen bonding between ammonia molecules, which requires significant energy to break. The thermodynamic properties of ammonia, including its boiling point, are well-documented and have been extensively studied to develop accurate equations of state for various applications.

4. Melting Point

This low melting point is also a result of the hydrogen bonding between ammonia molecules, which influences its phase transitions. The melting point is a critical parameter in understanding the behavior of ammonia under different temperature conditions, especially in applications involving cryogenics and low-temperature chemistry.

5. Density

The density of liquid ammonia at its boiling point is approximately 0.682 g/cm³. The density varies with temperature and pressure, and accurate measurements are essential for various industrial applications. The density of ammonia-water mixtures has also been studied extensively, showing that ammonia can form neutrally buoyant liquids relative to its solid phases, which has implications for planetary science and cryovolcanism.

6. Solubility

Ammonia is highly soluble in water and various ionic liquids. Its solubility in water leads to the formation of ammonium hydroxide, a common laboratory reagent. The solubility of ammonia in ionic liquids and deep eutectic solvents has been studied for potential applications in absorption cooling and heating cycles. These studies show that ammonia’s solubility is influenced by temperature, pressure, and the nature of the solvent.

7. Vapor Pressure

The vapor pressure of ammonia is relatively high due to its low boiling point. At 25°C, the vapor pressure of ammonia is about 8.5 bar (850 kPa). This high vapor pressure is a critical factor in its use in refrigeration and air conditioning systems, where ammonia is valued for its efficiency and effectiveness as a refrigerant. The vapor pressure also plays a significant role in the safety and handling of ammonia in industrial applications.

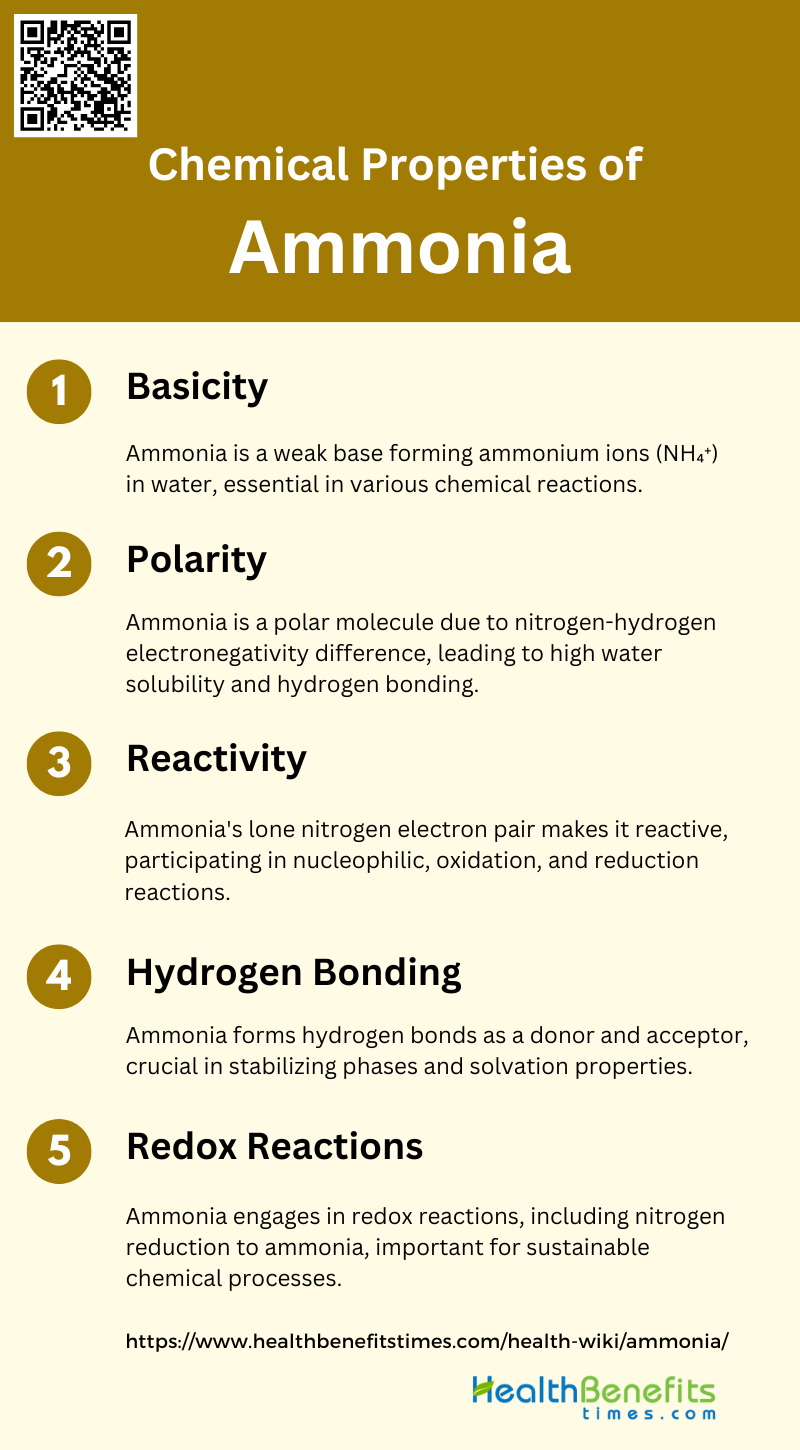

Chemical Properties of Ammonia

It acts as a weak base, readily forming ammonium ions (NH₄⁺) in aqueous solutions. Below are some key chemical properties of ammonia:

1. Basicity

Ammonia (NH₃) is a weak base, primarily due to the lone pair of electrons on the nitrogen atom, which can accept a proton (H⁺) to form ammonium (NH₄⁺) ions. This property is fundamental in various chemical reactions, including the formation of ammonium salts. The basicity of ammonia is also influenced by its ability to form hydrogen bonds, which stabilizes the ammonium ion in aqueous solutions. Theoretical studies have shown that ammonia’s basicity is crucial in its role in hydrogen-bonded systems and ionic crystal formation under high pressure. Additionally, ammonia’s basicity is leveraged in aminolysis reactions, where it acts as a nucleophile.

2. Polarity

This polarity is responsible for ammonia’s high solubility in water and its ability to form hydrogen bonds. The dipole moment of ammonia plays a crucial role in its interactions with other polar molecules and ions, which is evident in its behavior in various chemical processes, including its role as a “strong” collider in third-molecular reactions. The polar nature of ammonia also contributes to its solvation properties, as seen in its interaction with atomic sodium.

3. Reactivity

It can act as a nucleophile, forming bonds with electrophiles, and can also undergo oxidation and reduction reactions. The reactivity of ammonia is influenced by its ability to form hydrogen bonds and its polar nature. For instance, ammonia can inhibit hydrogen reactivity in oxidation processes, demonstrating its role in mutual inhibition effects in combustion chemistry. Additionally, ammonia’s reactivity is crucial in the electrochemical synthesis of ammonia, where it participates in nitrogen reduction reactions.

4. Hydrogen Bonding

This property is fundamental to its behavior in various chemical and physical processes. The hydrogen bond donor ability of ammonia has been investigated with different chalcogen atoms, showing that ammonia can form N-H···O, N-H···S, and N-H···Se hydrogen bonds. These interactions are crucial in stabilizing ammonia in different phases and under various conditions. The hydrogen bonding capability of ammonia also plays a significant role in its solvation properties and its behavior under high pressure, where it can form hydrogen-bonded solids.

5. Redox Reactions

In the context of electrochemical synthesis, ammonia can be produced through the nitrogen reduction reaction (NRR), where nitrogen (N₂) is reduced to ammonia (NH₃) using renewable electricity. This process is an alternative to the energy-intensive Haber-Bosch process and highlights the importance of ammonia in sustainable chemical processes. Additionally, ammonia’s role in oxidation processes, particularly in combustion chemistry, demonstrates its ability to influence redox reactions by inhibiting hydrogen reactivity.

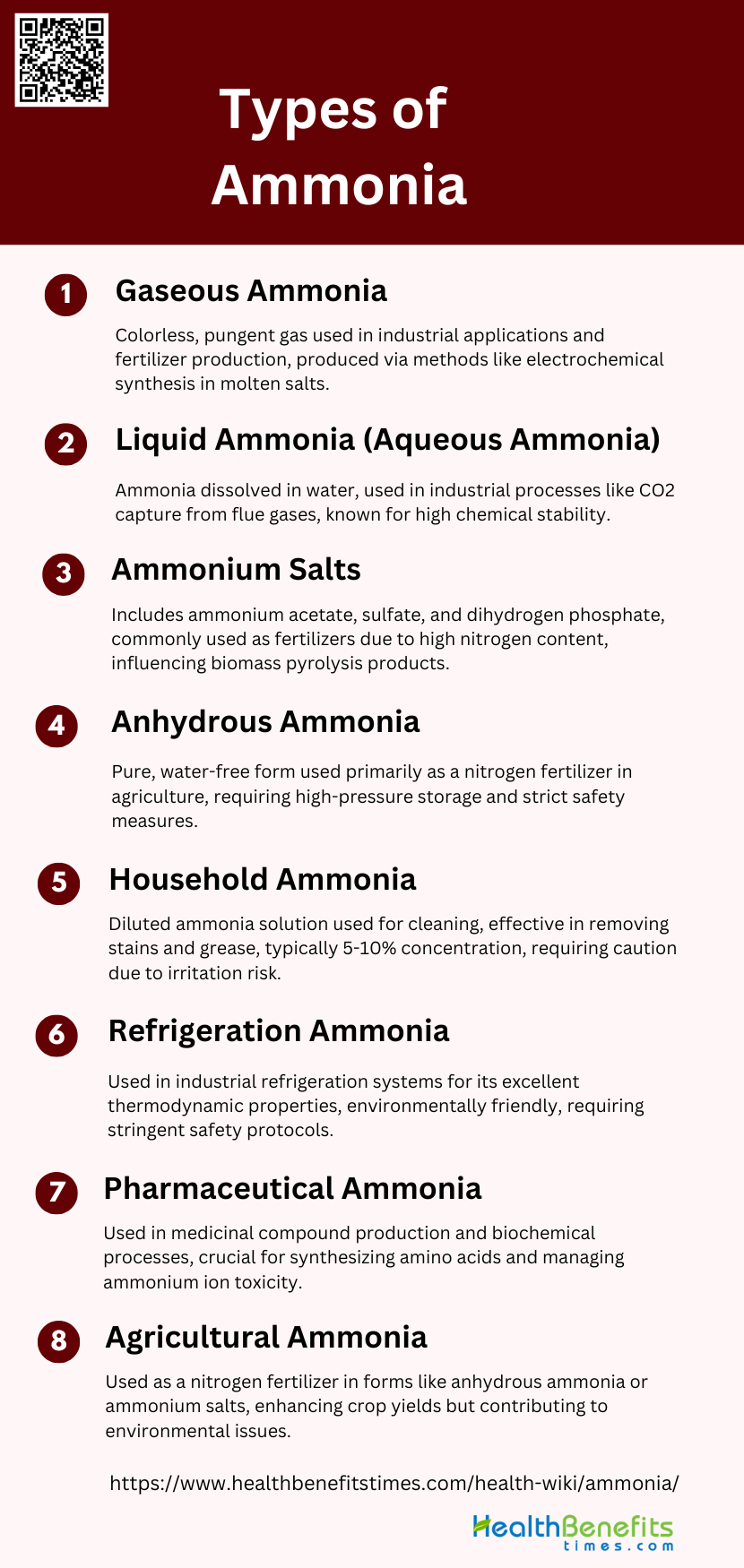

Types of Ammonia

Understanding these types is crucial for their effective use in industrial, agricultural, and household contexts. Below is a list of the main types of ammonia:

1. Gaseous Ammonia

Gaseous ammonia (NH3) is a colorless gas with a pungent odor, commonly used in industrial applications such as the production of fertilizers and chemicals. It is also a key feedstock for the synthesis of various nitrogen-containing compounds. The electrochemical synthesis of ammonia in molten salts is one promising method for producing gaseous ammonia, offering an alternative to the traditional Haber-Bosch process. This method leverages the strong solubility of N3- ions and the wide potential window of molten salt electrolytes to enhance the efficiency of ammonia production.

2. Liquid Ammonia (Aqueous Ammonia)

Liquid ammonia, often referred to as aqueous ammonia, is a solution of ammonia in water. It is widely used in industrial processes, including the capture of CO2 emissions from flue gases. Aqueous ammonia is favored for its high chemical stability and CO2 removal capacity. Recent advancements in aqueous ammonia-based post-combustion CO2 capture technologies have focused on improving its economic viability by addressing issues related to its high volatility and low reactivity towards CO2. Notable developments include General Electric’s chilled NH3 process and CSIRO’s mild-temperature aqueous NH3 process.

3. Ammonium Salts

These salts are often employed as fertilizers due to their high nitrogen content. In the context of biomass pyrolysis, the introduction of ammonium salts can significantly influence the composition of the resulting products. For instance, urea-impregnated biomass produces a higher content of nitrogenous heterocyclic compounds and phenols, while ammonium sulfate and ammonium dihydrogen phosphate reduce the quantity of liquid products and increase the production of CO and H2 gases.

4. Anhydrous Ammonia

Anhydrous ammonia is ammonia in its pure, water-free form. It is a critical component in the agricultural industry, primarily used as a nitrogen fertilizer. Anhydrous ammonia is stored and transported under high pressure to maintain its liquid state. Its application in agriculture is highly efficient, as it provides a readily available source of nitrogen to plants. However, handling anhydrous ammonia requires strict safety measures due to its corrosive nature and potential health hazards upon exposure.

5. Household Ammonia

Household ammonia is a diluted solution of ammonia in water, typically used for cleaning purposes. It is effective in removing stains, grease, and grime from various surfaces. The concentration of ammonia in household cleaning products is usually around 5-10%. While it is a versatile and powerful cleaning agent, it should be used with caution, as inhaling its fumes or direct contact with skin can cause irritation. Proper ventilation and protective gear are recommended when using household ammonia for cleaning tasks.

6. Refrigeration Ammonia

Refrigeration ammonia, also known as anhydrous ammonia, is widely used in industrial refrigeration systems due to its excellent thermodynamic properties. It is highly efficient in heat absorption and transfer, making it an ideal refrigerant for large-scale cooling applications. The use of ammonia in refrigeration systems is environmentally friendly, as it does not contribute to ozone depletion or global warming. However, the handling and storage of refrigeration ammonia require stringent safety protocols to prevent leaks and exposure.

7. Pharmaceutical Ammonia

Pharmaceutical ammonia is used in the production of various medicinal compounds and as a reagent in biochemical processes. It plays a crucial role in the synthesis of amino acids and other nitrogen-containing compounds essential for cellular functions. The balance of ammonium ions in biological systems is vital, as their accumulation can lead to toxicity and tissue damage. Research into the enzymes and transporters that regulate ammonium fluxes in plant tissues is ongoing, aiming to develop methods to manage ammonium toxicity and improve plant health.

8. Agricultural Ammonia

Agricultural ammonia, primarily in the form of anhydrous ammonia or ammonium salts, is extensively used as a nitrogen fertilizer to enhance crop yields. Its application provides a direct source of nitrogen, which is essential for plant growth and development. The use of ammonia-based fertilizers has revolutionized modern agriculture, significantly increasing food production. However, the environmental impact of ammonia runoff and its contribution to soil acidification and water pollution are areas of concern that require ongoing research and management.

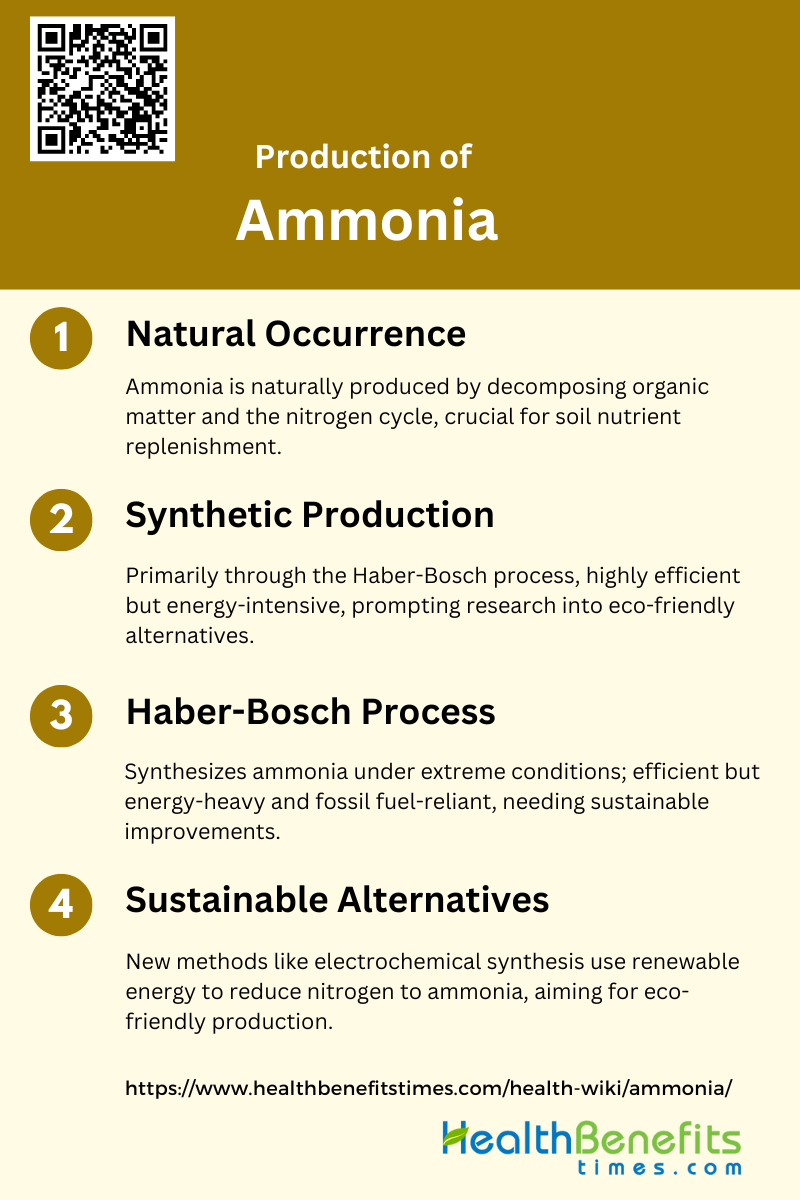

Production of Ammonia

The production of ammonia is a critical industrial process with significant applications in agriculture, chemical manufacturing, and other sectors. Various methods are employed to produce ammonia, each with its own advantages and challenges. Below is a list of the primary methods used in ammonia production:

1. Natural Occurrence

Microorganisms play a crucial role in the nitrogen cycle, converting nitrogen from the atmosphere into ammonia through biological nitrogen fixation. This process is facilitated by the enzyme nitrogenase, which is found in certain bacteria and archaea. These microorganisms are often associated with the roots of leguminous plants, forming symbiotic relationships that benefit both the plant and the bacteria. The naturally occurring ammonia is essential for plant growth, as it is a key component of the nitrogen cycle, which replenishes soil nutrients and supports agricultural productivity.

2. Synthetic Production

The synthetic production of ammonia is predominantly achieved through the Haber-Bosch process, which has been the cornerstone of industrial ammonia synthesis since the early 20th century. This process involves the reaction of nitrogen (N₂) from the air with hydrogen (H₂) derived from natural gas or coal, under high temperatures and pressures, in the presence of an iron catalyst. Despite its efficiency in producing large quantities of ammonia, the Haber-Bosch process is highly energy-intensive and contributes significantly to global greenhouse gas emissions. Efforts to develop alternative methods for ammonia synthesis, such as electrochemical and plasma-assisted processes, aim to reduce the environmental impact and energy consumption associated with traditional ammonia production.

3. Haber-Bosch Process

The Haber-Bosch process is a critical industrial method for synthesizing ammonia, which is essential for fertilizers and various chemicals. This process operates under extreme conditions, typically at temperatures of 400-500°C and pressures of 150-300 bar, using an iron-based catalyst to facilitate the reaction between nitrogen and hydrogen gases. While the Haber-Bosch process has enabled large-scale ammonia production, it is also associated with significant energy consumption and carbon dioxide emissions, as it relies heavily on fossil fuels. Innovations in catalyst development and process optimization are ongoing to improve the efficiency and sustainability of this century-old technology.

4. Sustainable Alternatives

Sustainable alternatives to the Haber-Bosch process are being actively researched to address the environmental and energy challenges associated with traditional ammonia synthesis. Electrochemical ammonia synthesis, which uses renewable energy sources such as solar or wind power to drive the reduction of nitrogen to ammonia, presents a promising alternative. This method operates under milder conditions and has the potential to significantly reduce carbon emissions. Other emerging technologies include plasma-assisted synthesis, photocatalytic methods, and the use of non-thermal plasma, all of which aim to achieve ammonia production with lower energy inputs and reduced environmental impact. These innovative approaches are crucial for transitioning to a more sustainable ammonia economy.

Uses of Ammonia

Its unique properties make it invaluable in agriculture, manufacturing, and even household cleaning. Below is a list of the primary uses of ammonia:

1. Fertilizer Production

This process is essential for meeting the global food demand by enhancing crop yields. However, the traditional method is energy-intensive and environmentally unsustainable. Recent research suggests that renewable ammonia, produced using hydrogen from renewable-powered electrolysis and nitrogen from air, could offer a more sustainable alternative. This approach not only addresses environmental concerns but also provides a low-cost storage medium for intermittent renewable energy.

2. Refrigeration

It is particularly favored in industrial refrigeration systems for its efficiency and cost-effectiveness. However, ammonia’s toxicity and flammability pose safety challenges. Advances in ammonia refrigeration technology focus on improving safety measures and reducing environmental impact, making it a viable option for sustainable cooling solutions.

3. Cleaning Products

Its alkaline nature makes it particularly useful for cleaning glass, tiles, and other hard surfaces. However, the use of ammonia in cleaning products requires careful handling to avoid inhalation or skin contact, which can cause irritation. Research into safer formulations and alternatives continues to ensure effective cleaning while minimizing health risks.

4. Water Treatment

Ammonium ions, derived from ammonia, are often targeted for recovery in wastewater treatment plants to reduce environmental pollution and recycle valuable resources. Technologies for ammonium recovery are being developed to enhance the efficiency and economic feasibility of these processes, contributing to sustainable wastewater management.

5. Pharmaceuticals

In the pharmaceutical industry, ammonia is used in the synthesis of various drugs and active pharmaceutical ingredients. Its role as a reagent in chemical reactions makes it indispensable for producing medications that treat a wide range of conditions. The pharmaceutical applications of ammonia require stringent quality control to ensure the purity and safety of the final products. Ongoing research aims to optimize these processes for better efficiency and sustainability.

6. Textile Industry

Ammonia is utilized in the textile industry for processes such as mercerization, which enhances the strength, luster, and dye affinity of cotton fabrics. It is also used in the production of synthetic fibers and as a neutralizing agent in dyeing processes. The use of ammonia in textiles helps improve the quality and durability of fabrics, making it a valuable chemical in textile manufacturing.

7. Explosives

Ammonia is a key ingredient in the production of explosives, particularly ammonium nitrate, which is widely used in mining, construction, and military applications. The high nitrogen content of ammonia makes it an effective oxidizing agent, essential for explosive reactions. Safety and environmental concerns are paramount in the handling and use of ammonia-based explosives, driving research into safer and more sustainable alternatives.

8. Pulp and Paper Industry

In the pulp and paper industry, ammonia is used in the pulping process to break down lignin and separate cellulose fibers. This process, known as ammonia-based pulping, offers advantages such as reduced energy consumption and lower environmental impact compared to traditional methods. Research continues to explore the optimization of ammonia use in pulping to enhance efficiency and sustainability in paper production.

9. Rubber Industry

It is also involved in the vulcanization process, which improves the elasticity and strength of rubber products. The use of ammonia in rubber manufacturing ensures the quality and durability of a wide range of rubber goods, from tires to medical devices.

10. Ammonia in Environmental Control

Ammonia plays a crucial role in environmental control, particularly in the reduction of nitrogen oxides (NOx) emissions from industrial processes and combustion engines. Ammonia-based selective catalytic reduction (SCR) systems are widely used to convert NOx into harmless nitrogen and water, thereby reducing air pollution. Research into improving the efficiency and effectiveness of these systems is ongoing, contributing to cleaner air and a healthier environment.

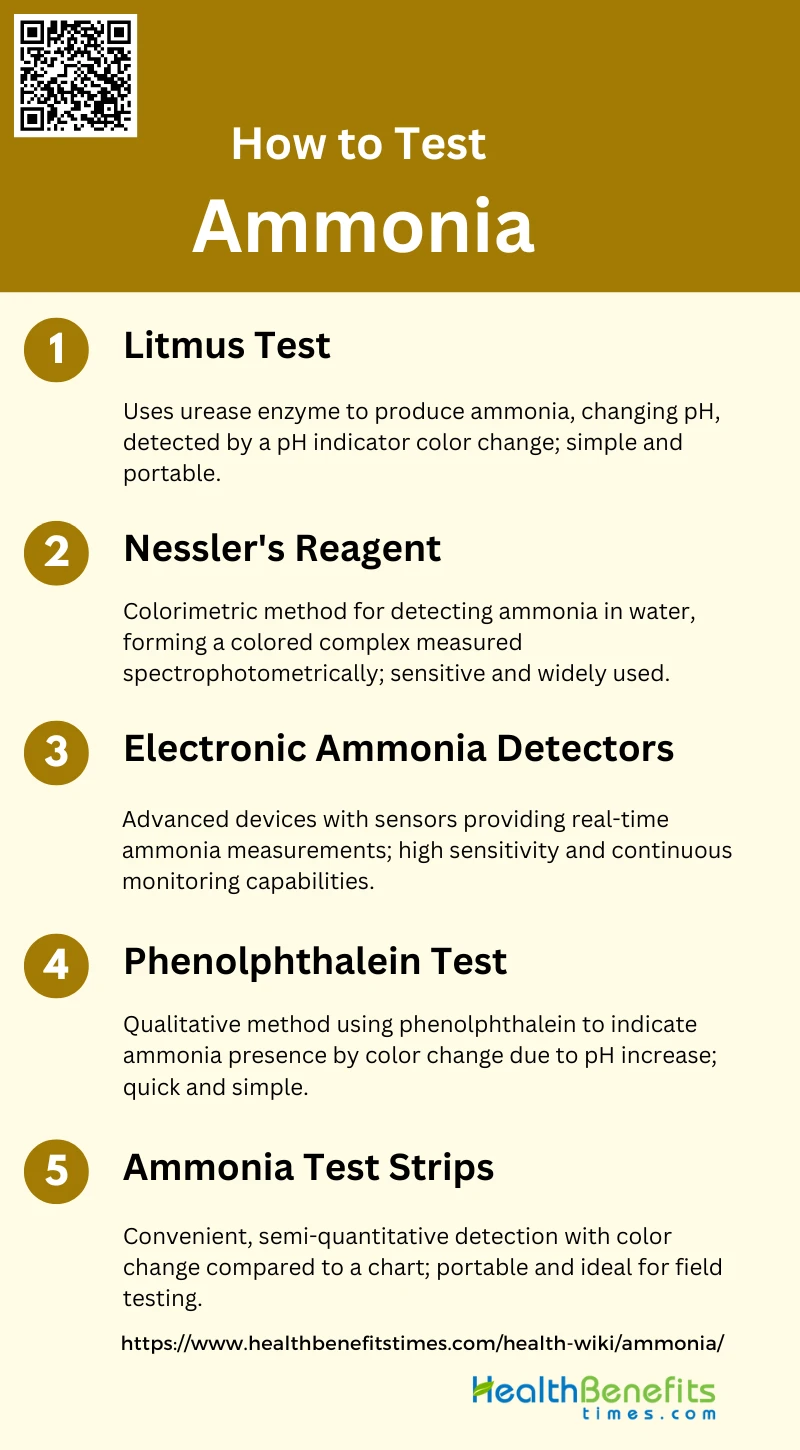

How to test ammonia?

Testing for ammonia can be done using several methods, depending on the context and the required sensitivity. Here are some common methods:

1. Litmus Test

The litmus test is a simple and effective method for detecting ammonia through a color change that indicates pH levels. This method involves the use of urease, an enzyme that hydrolyzes urea to produce ammonia, thereby increasing the pH of the solution. The change in pH is then monitored using a pH indicator, which changes color in response to the presence of ammonia. This method is advantageous due to its simplicity, portability, and ease of use, making it suitable for field applications and resource-limited settings. It has been effectively used for detecting specific pathogens and DNA mismatches, demonstrating its versatility and practical application in various fields.

2. Nessler’s Reagent

Nessler’s reagent is a widely used method for the colorimetric determination of ammonia nitrogen in water. This method involves the addition of Nessler’s reagent to a water sample, which reacts with ammonia to form a colored complex. The intensity of the color is proportional to the ammonia concentration and can be measured spectrophotometrically. Despite its sensitivity and simplicity, the method is influenced by several factors such as reagent preparation, preservation, and experimental conditions. Proper control of these factors is essential to ensure accurate and reliable results. This method is commonly used in various applications, including water quality analysis and aquaculture.

3. Electronic Ammonia Detectors

Electronic ammonia detectors are advanced devices that provide real-time and accurate measurements of ammonia concentrations. These detectors typically use sensors that respond to the presence of ammonia by generating an electrical signal proportional to the ammonia concentration. They offer several advantages, including high sensitivity, rapid response, and the ability to continuously monitor ammonia levels. However, their performance can be affected by the presence of interferants and environmental conditions. Despite these challenges, electronic ammonia detectors are valuable tools in various applications, including industrial monitoring, environmental analysis, and safety assessments.

4. Phenolphthalein Test

The phenolphthalein test is a qualitative method for detecting ammonia based on the pH change induced by ammonia in a solution. Phenolphthalein is a pH indicator that changes color in response to pH variations. In the presence of ammonia, the pH of the solution increases, causing phenolphthalein to change from colorless to pink. This method is simple and quick, making it suitable for preliminary screening and field applications. However, it is less sensitive and quantitative compared to other methods such as Nessler’s reagent or electronic detectors. It is often used in conjunction with other methods to confirm the presence of ammonia.

5. Ammonia Test Strips

Ammonia test strips are convenient and easy-to-use tools for the semi-quantitative detection of ammonia in various samples. These strips are impregnated with reagents that react with ammonia to produce a color change. The intensity of the color can be compared to a color chart to estimate the ammonia concentration. Test strips are portable, require no special equipment, and provide rapid results, making them ideal for field testing and on-site analysis. However, they may have limitations in terms of sensitivity and accuracy compared to more sophisticated methods. They are commonly used in applications such as water quality testing, aquaculture, and environmental monitoring.